We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Ordering Code

| Qty | Unit price |

|---|---|

| 1+ | $ 89.71 |

| 10+ | $ 68.69 |

| 20+ | $ 58.59 |

| 50+ | $ 48.93 |

| 100+ | $ 43.32 |

Features:

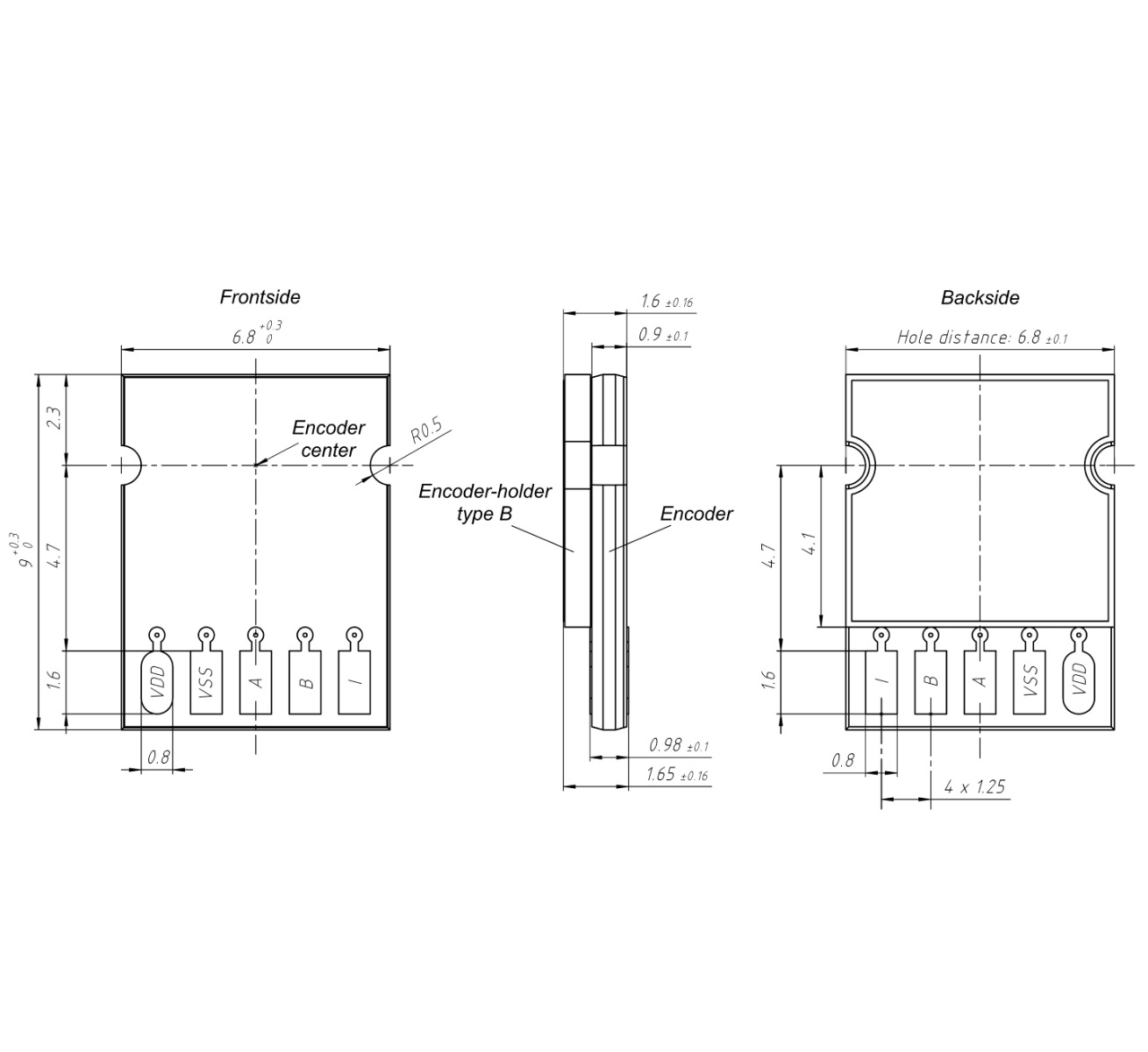

- Highly miniaturized: 6.8 x 9 x 1 mm

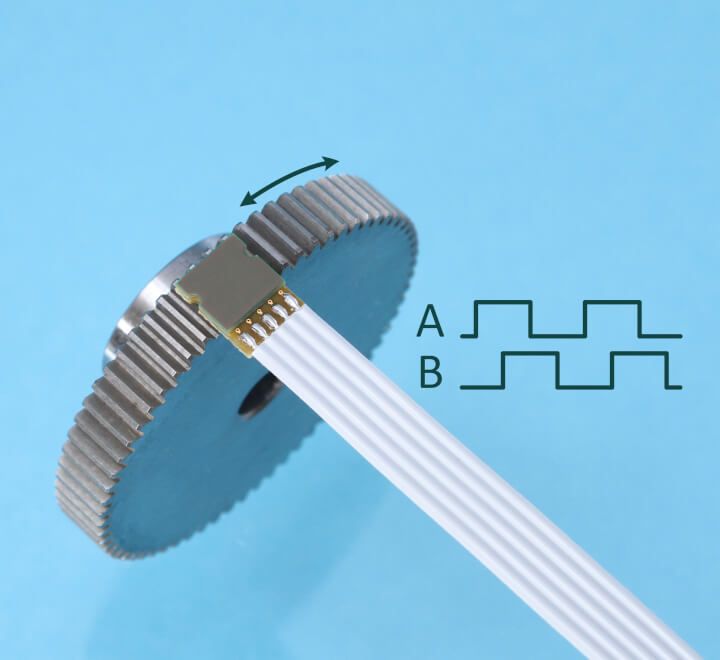

- Outputs A quad B

- Robust against oil grease, liquids, dust, particles

- Programmable resolution and max speed

- Optional with holder, cable and connector

The ID1102G inductive gear speed sensor consists of a sensor and a gearwheel. The sensor is an integrated circuit in a PCB housing. It provides incremental A and B output signals in quadrature. The gearwheel is in ferromagnetic steel and has a module 0.5.

The resolution and the maximum speed of the sensor are user-programmable or can be programmed ex-factory.

| Output signals | A quad B |

| Interpolation | up to x16’384 |

| Speed | 0 up to 23’000 RPM |

| Tooth frequency | 0 up to 25 kHz |

| A/B frequency | 0 up to 1 MHz |

| Supply | 5V, 10 mA |

| Temperature | -20 to 100°C |

| Airgap | 0.1 – 0.6 mm |

The inductive gear speed sensor ID1102G can be operated with a gear made of ferromagnetic material and with module 0.5. POSIC uses gears from the company NOZAG, the datasheet of these gears is under the downloads tab.

The sensor is not intended for operation with non-ferromagnetic gears.

The sensor is not intended for operation with gears with module < 0.4 or module > 0.6.

Dimensions (mm) of ID1102 encoder on encoder-holder type B.

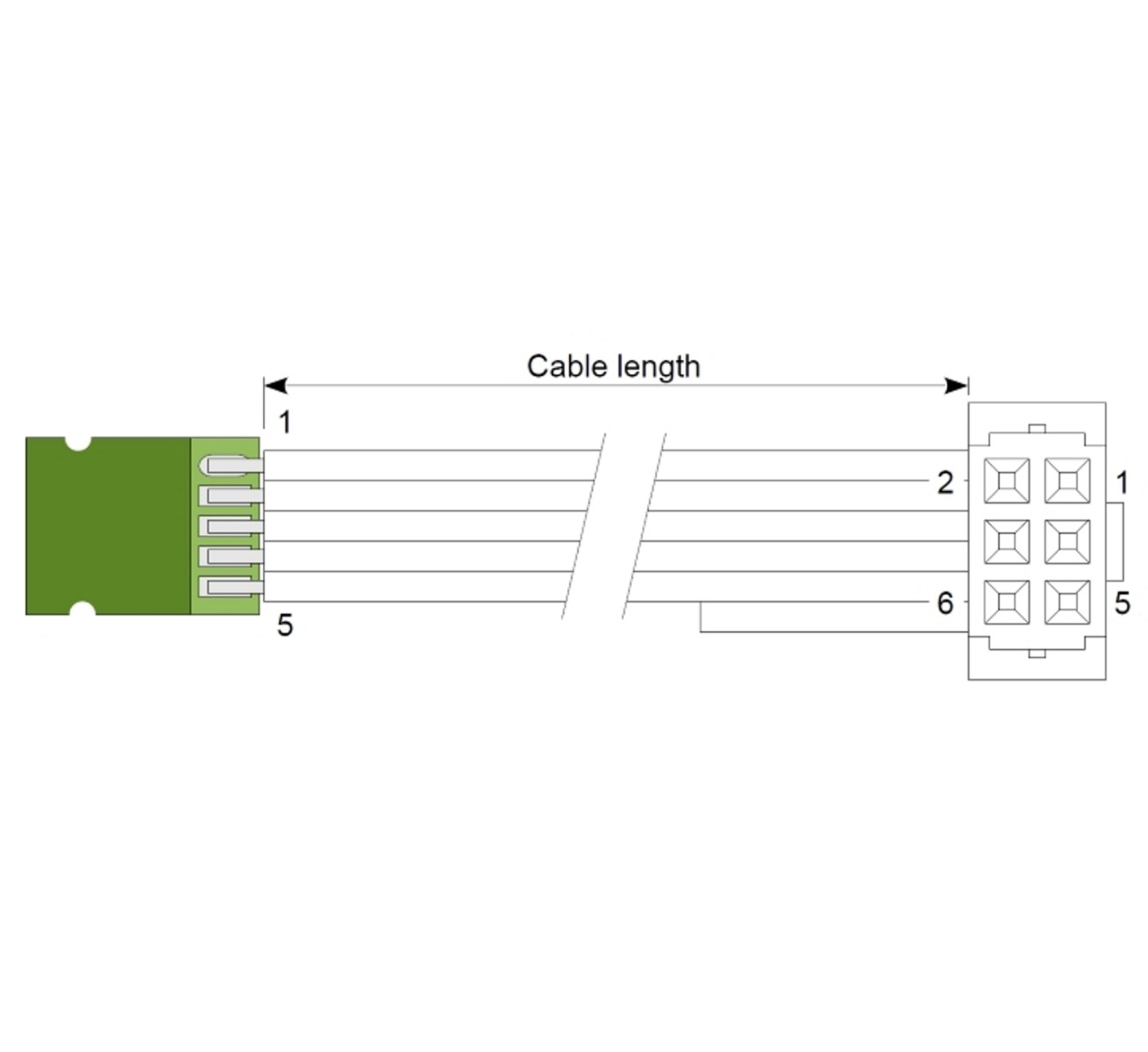

Encoder with flat cable (pitch 1.27 mm) and 6-pin DIN41651 connector.

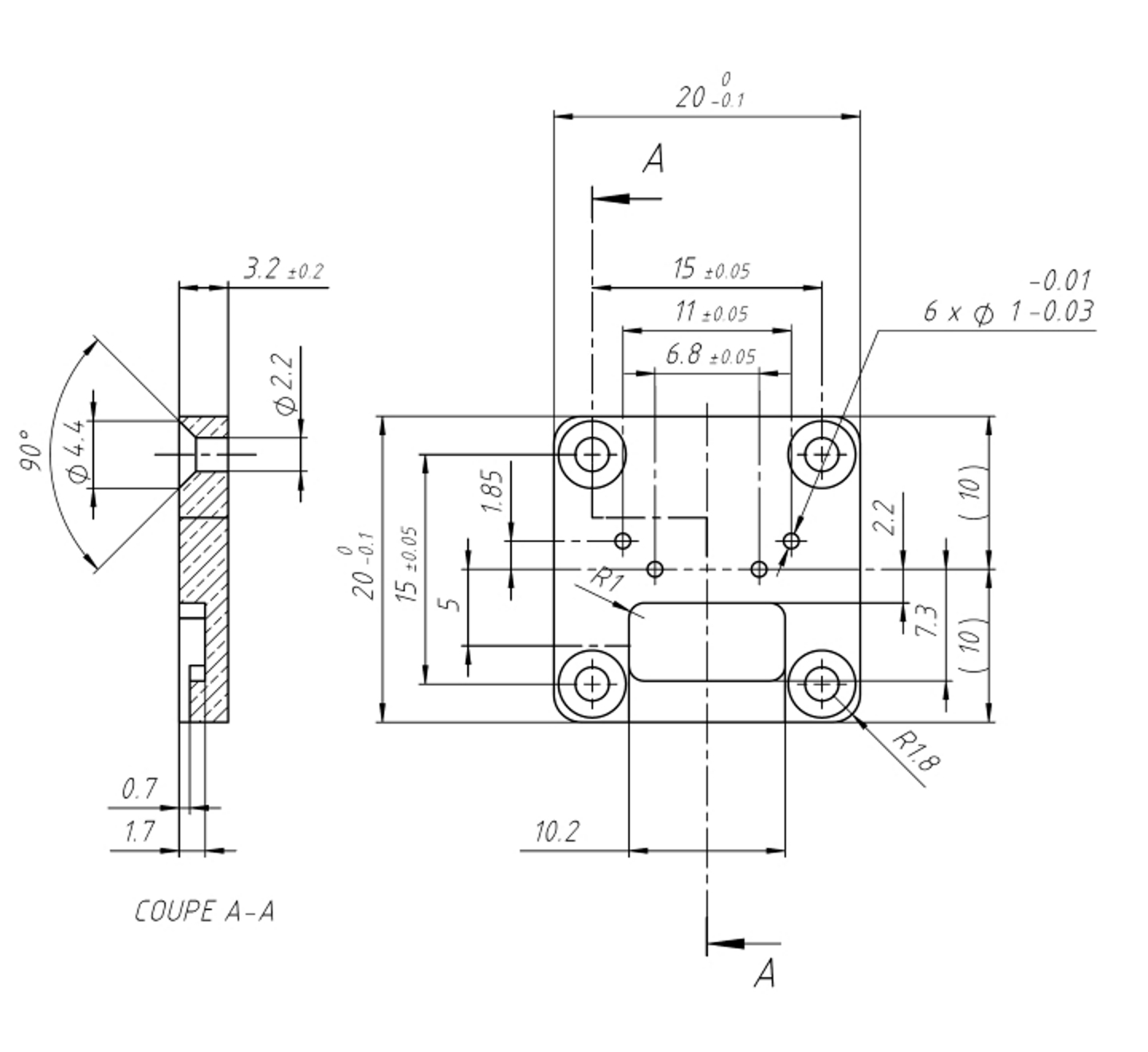

Dimensions (mm) of encoder-holder type A. This holder is only available for evaluation purposes as part of the Evaluation & Programming Tool. If you intend to use holder type A for series production, please select the ID4501 encoder.