We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

FAQ

What is the lead time for an Evaluation & Programming Tool?

From order to shipment: 2 weeks

What is the lead time for encoders, scales and codewheels?

The lead time (from order to shipment) depends on the quantity:

1 - 19 pcs: 2 weeks

20 - 99 pcs: 4 weeks

100 - 999 pcs: 6 weeks

≥1000 pcs: contact POSIC

How long does the shipping take?

Within Switzerland by Postal services: next day delivery

Within Europe by Fedex: typically 2 - 3 working days

Rest of world by FedEx: typically 3 - 5 working days

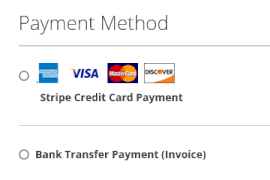

Which payment methods are available?

During checkout you can select the payment method as illustrated below: credit card or bank transfer payment.

In the case of bank transfer, you will receive an invoice with our bank information for wire transfer.

We do not accept checks or other payment methods.

In which currencies can I pay?

At the top of the page you can select USD (United States Dollar), EUR (Euro) or CHF (Swiss Franc). You can change currencies up to the moment of payment.

What is the shipment cost?

The shipment cost depends on the destination:

- In Switzerland by Post: CHF 10.-

- In Europe by FedEx: EUR 45.-

- Outside Europe by FedEx: USD 65.-

Are POSIC encoders working correctly at zero speed?

Yes, the sensing principle in a POSIC encoder is a differential transformer. The primary coil generates a magnetic field, the secondary coils measure the magnetic field, which is modulated by the scale or codewheel. This mechanism works perfectly if the codewheel or scale is not moving.

More detailed explanations can be found on POSIC's Technology-page.

Are POSIC encoders sensitive to magnetic fields generated by magnets, coils, direct drives etc.?

The POSIC encoder is a differential transformer. The primary coil generates a high-frequency (1 – 2 MHz) magnetic field and measures this field back using the secondary coils. Perturbations below 1 MHz are filtered out. As most magnetic fields from magnets, motors, drives etc. are well below 1 MHz, these magnetic fields do not influence the encoder. On above, the secondary coils in the encoder are arranged in a differential way, so that a magnetic field acting on two differential measurement coils is eliminated.

So POSIC encoders are not sensitive to magnetic fields.

More detailed explanations can be found on POSIC's Technology page.

Do inductive encoders have hysteresis?

No, inductive encoders have no "magnetic hysteresis". However, for signal-stability, POSIC encoders with A/B/I-outputs have an electronic hysteresis of one A/B state.

Can the encoder be damaged due to strong magnetic fields?

No, to our knowledge and experience, POSIC encoders cannot be damaged due to strong magnetic fields.

Can I configure and program a POSIC encoder by myself?

Yes, you can configure POSIC encoders using the Evaluation & Programming Tool in combination with the ASSIST software.

How can I check if my encoder is connected and working correctly?

The best option is the ASSIST Software, it allows to:

- Measure the supply voltage and current

- Check the A, B and I signals for short-circuits and open-circuits

- Verify the the chip is damaged by mechanical impact or electrostatic discharge by measuring the static leakage current

- Dump the encoder's OTP memory in a text file and send it to POSIC for verification

Detailed explanations can be found in the ASSIST User-Manual.

What is the linearity of a POSIC encoder?

The linearity depends on the dimensions and materials of the scale/codewheel, the airgap and the mechanical tolerances.

The encoder contains a LUT (LookUp Table) to compensate the non-linearity, this can be done with an individual linearization of each encoder or with a standard LUT for a specific scale/codewheel at a specific airgap.

- Without linearization, the non-linearity with a POSIC scale is typically +/- 40 um.

- With a standard LUT, the non-linearity with a POSIC scale is typically +/- 25 um.

- After individual linearization, the non-linearity with a POSIC scale is typically +/- 5 to +/- 10 um.

Please note that the overall accuracy is the sum of the non-linearity of the encoder and the inaccuracy of the scale, codewheel or gear.

Is the encoder sensitive to metal objects behind it?

The encoders mounted on a holder Type A or B are screened against metal objects behind the encoder, so they can be mounted on any metallic or non-metallic surface. Cabled encoders without holder are sensitive to metallic object behind the encoder, so they should be mounted on a non-metallic surface of at least 2 mm thickness. SMD encoders without holder are sensitive to metallic objects behind the encoder, so they should be mounted on a PCB without copper traces behind the encoder as explained in the recommended footprint in the datasheet.

Can the encoder be damaged due to strong magnetic fields?

No, to our knowledge and experience, POSIC encoders cannot be damaged due to strong magnetic fields.

Can I make my own scale or codewheel?

Yes! Scales and discs are straightforward PCBs (Printed Circuit Boards) with copper strips on the frontside and a plain copper layer on the backside that acts as a screen against metal objects behind the scale or disc. The PCB consists of 0.6 mm FR-4 (or thicker), 35 um copper and a protective layer (typically solder mask or nickel/gold finish).

Contact POSIC for more detailed info.

Can I measure until the end of a scale or should I leave some space at the end?

You should leave at least 1 period between the center of the encoder and the end of the scale. More detailed information is given in the Assembly Guide.

What is the accuracy of a scale or codewheel?

The accuracy of a scale or codewheel is detemined by the accuracy of the copper patterns, which is typically +/- 10 um for lenghts up to about 200 mm.

Please note that the overall accuracy is the sum of the non-linearity of the encoder and the inaccuracy of the scale, codewheel or gear.

Can I cut my scale to a specific length?

Yes! You can cut, machine, saw or grind your scale to a specific length. Our recommendations:

- cut between two copper strips

- avoid delamination of the backside copper layer

- avoid mechanical deformation of the scale: avoid clamping too tight and avoid bending and twisting

Can I measure a steel gear with a POSIC encoder?

Yes, we have two Gear Speed Sensors that are suitable for operation with a steel gear.

The gear must be ferromagnetic (a magnet should stick to the gear) and have module 0.5 (teeth-pitch about 1.6 mm).

Can I measure an aluminum gear with a POSIC encoder?

An aluminum gear can only be used if the module is 0.8. Smaller or bigger modules or other tooth shapes are not working correctly.

Can strong magnetic fields damage scales or codewheels?

No, scales and codewheels are made of non-magnetic materials and their properties cannot be changed by strong magnetic fields